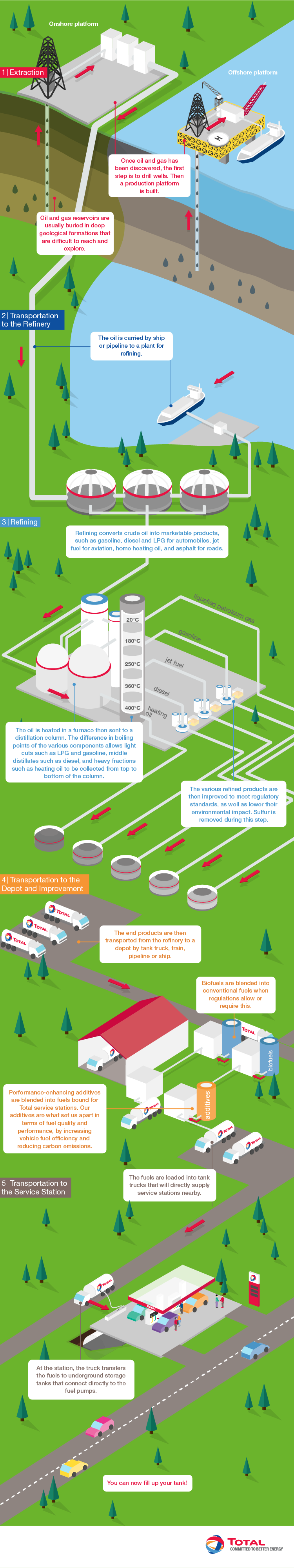

From Well to Pump

05/06/2020

Slide down the animation by clicking on the arrow or on the titles ABCDE

See additional information , photos and how oil is extracted

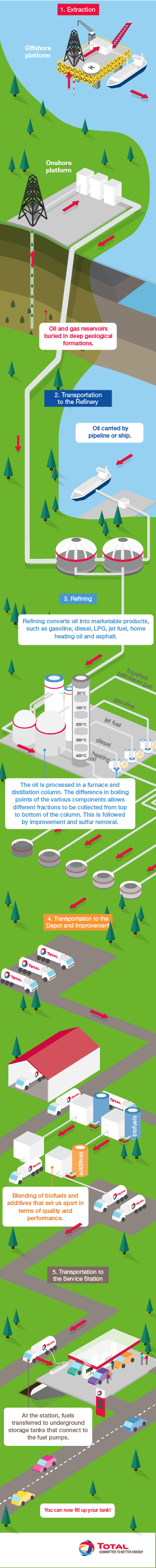

Whether the reservoir is onshore or offshore, the process is the same: once oil and gas has been discovered, the first step is to drill wells. Then a production platform is built.

Oil and gas reservoirs are usually buried in deep geological formations that are difficult to reach and explore.

Oil extracted onshore is piped to a refinery.

Oil produced offshore is first stored on site, then carried by ship or pipeline to a plant for refining.

Refining converts crude oil into marketable products, such as gasoline, diesel and LPG for automobiles, jet fuel for aviation, home heating oil, and asphalt for roads.

The oil is heated in a furnace then sent to a distillation column. The difference in boiling points of the various components allows light cuts such as LPG and gasoline, middle distillates such as diesel, and heavy fractions such as heating oil to be collected from top to bottom of the column.

More heavy than light products are usually obtained, which is out of sync with market demand. So the heavy oil and gas molecules are cracked to obtain lighter products such as diesel, which is in very high demand in Europe.

The various refined products are then improved to meet regulatory standards, as well as lower their environmental impact. Sulfur is removed during this step, for example.

The end products are then transported from the refinery to a depot by tank truck, train, pipeline or ship.

At the depot, performance-enhancing additives are blended into fuels bound for Total service stations. Our additives are what set us apart in terms of fuel quality and performance, by increasing vehicle fuel efficiency and reducing carbon emissions.

Depots are also where biofuels are blended into conventional fuels when regulations allow or require this. The same step is carried out right at the refinery in the case of diesel.